Digital Crown & Bridge | Bremadent Dental Laboratory in London

We train all our technicians in-house on the PTC system to maintain and monitor our crown & bridge standard. The PTC system ensures consistent results from aesthetics to occlusion, function to fit and margins to contact areas. Due to our technicians having a in depth understanding, it allows us to confidently ensure long lasting, aesthetically pleasing functional restorations that benefits the patient, clinician and laboratory.

Technical Features

Intraoral scan (Recommended)

1) We can import and design straight from your intraoral scan either through the intra oral scanners portal if you add us as your preferred dental laboratory or you can send the .stl file sent via email to [email protected]. This will introduce the least amount of variables. Accuracy of the scan data: Analogue models or casts

2) We can scan directly from working models, analogue implant impressions, single or triple trays with one scan without the need to introduce variables e.g expansion rates, human error, chipped or broken teeth etc. The Accuracy is ISO 12836 with crown & bridge at 5 microns and implants at 8 microns.

Accuracy of design:

Once digitally scanned, the parameters of the prepared tooth, margins, occlusion is defined clearly and the parameters are locked with any areas of concern, customised within the locked parameters. The restoration can then be designed and altered with our natural anatomy library within the locked parameters.

Accuracy of CAM milled restoration:

The parameters of the scan & design are locked and cannot be altered further, the restoration is then milled from the locked parameters and then is pre-sintered in a controlled furnace. Once the restoration has been made, it is then fitted to a working model or 3D printed model with dies and then further to a solid model to minimize variables. This is then either stained & glazed or layered in ceramic dependent on the case. The restoration is then quality controlled for fit, aesthetics, occlusion, contact areas and margins.

Accuracy of 3D printed restoration

The 3D print is designed from the scan data, directly from the intraoral scan. All 3D printed models are printed at 50 microns with the patients name. This 3D print then undergoes a automated wash/dry cycle with clean isopropyl alcohol (IPA) solution and then cured with the correct wavelength of UV light.

Indications of use (scan & designed):

Anterior or posterior single crowns, full contoured crowns, inlays, onlays, veneers, bridges, abutments, implant bars, surgical guides, digital models, digital waxups.

Common materials used for restorations:

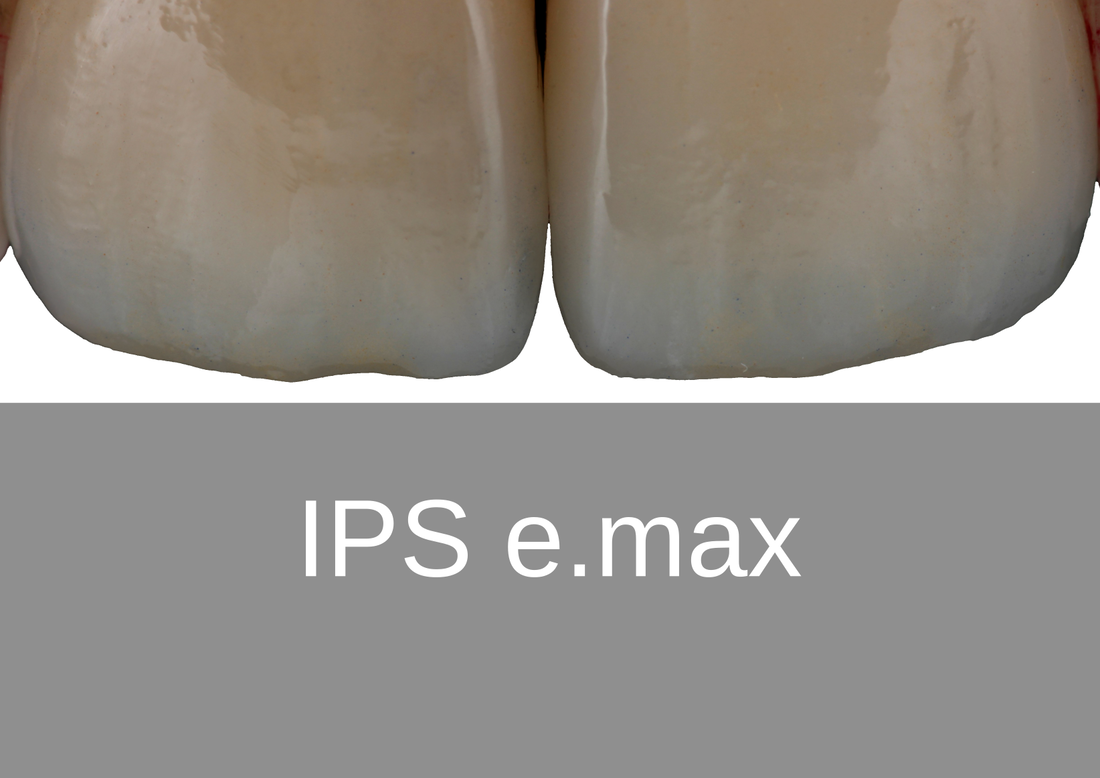

IPS e.max, Zirconia, PMMA, Titanium, Peekton, Cobalt Chrome (CoCr), Non-Precious and Semi Precious alloys.

To find out more information about Bremadent digital contact [email protected] for further information.

Technical Features

Intraoral scan (Recommended)

1) We can import and design straight from your intraoral scan either through the intra oral scanners portal if you add us as your preferred dental laboratory or you can send the .stl file sent via email to [email protected]. This will introduce the least amount of variables. Accuracy of the scan data: Analogue models or casts

2) We can scan directly from working models, analogue implant impressions, single or triple trays with one scan without the need to introduce variables e.g expansion rates, human error, chipped or broken teeth etc. The Accuracy is ISO 12836 with crown & bridge at 5 microns and implants at 8 microns.

Accuracy of design:

Once digitally scanned, the parameters of the prepared tooth, margins, occlusion is defined clearly and the parameters are locked with any areas of concern, customised within the locked parameters. The restoration can then be designed and altered with our natural anatomy library within the locked parameters.

Accuracy of CAM milled restoration:

The parameters of the scan & design are locked and cannot be altered further, the restoration is then milled from the locked parameters and then is pre-sintered in a controlled furnace. Once the restoration has been made, it is then fitted to a working model or 3D printed model with dies and then further to a solid model to minimize variables. This is then either stained & glazed or layered in ceramic dependent on the case. The restoration is then quality controlled for fit, aesthetics, occlusion, contact areas and margins.

Accuracy of 3D printed restoration

The 3D print is designed from the scan data, directly from the intraoral scan. All 3D printed models are printed at 50 microns with the patients name. This 3D print then undergoes a automated wash/dry cycle with clean isopropyl alcohol (IPA) solution and then cured with the correct wavelength of UV light.

Indications of use (scan & designed):

Anterior or posterior single crowns, full contoured crowns, inlays, onlays, veneers, bridges, abutments, implant bars, surgical guides, digital models, digital waxups.

Common materials used for restorations:

IPS e.max, Zirconia, PMMA, Titanium, Peekton, Cobalt Chrome (CoCr), Non-Precious and Semi Precious alloys.

To find out more information about Bremadent digital contact [email protected] for further information.

Bremadent Digital Crown & Bridge Services:

- IPS e.max: single unit anterior or posterior crowns, 3 unit anterior bridges, partial and full anatomical crowns, minimal veneers (from 0.3mm) , inlays & onlays and screw retained implant crowns

- Solid Zirconia: inlay/onlays, full contoured crowns, full contour bridges, copings, frameworks, retainers, custom implant abutments, hybrid bridges and layered ceramic crowns

- Zirconia substructure (for layering ceramic): Primary telescopic crowns, crown substructures, multi-unit bridge substructure with a maximum anatomical length of 47mm (4-6 unit bridge) and inlay bridges

- Implants: Single unit, bridge units, screw / cement retained customised abutments, implant bar and frameworks

- Metal / Gold: Single unit anterior or posterior crowns, partial and full anatomical crowns, crowns on dentures, inlays / onlays and screw / cement retained implant crowns

- Metal / Gold substructure: crown substructures for layering ceramic, multi-unit bridge substructures, customised implant abutments, precision attachments and telescopic crowns

- PMMA: Temporary crowns and bridges, diagnostic wax ups